Understanding Backorders: What They Are, Why They Happen, and How to Manage Them

Backorders happen. Still, your company can minimize its negative impact with a thoughtful strategy and the right software.

No customer wants to see that a coveted item is “backordered.” They’ll either have to shop elsewhere or wait weeks to receive their purchase.

It’s worse, though, for sellers. Backorders can disrupt revenue, damage customer experience, and increase administrative costs. Still, it’s hard to avoid them since no one can predict inventory needs with 100% accuracy.

In this guide, we’ll discuss what “backordered” means, how backorders happen, how they impact companies, and how software like a NetSuite Enterprise Resource Planning (ERP) system can minimize their issues.

At SuiteDynamics, we know how frustrating and hectic inventory management can get. Our experts will help your company streamline the backorder process using NetSuite software. We work with NetSuite to customize and implement ERPs for businesses large and small across various industries, and we can help boost your efficiency and productivity so customers stay satisfied.

What Does "Backordered" Mean?

A product is "backordered" when it is temporarily out of stock but will be available again after it is produced or a new inventory shipment is received. Customers can still purchase backordered items and receive them at later dates. These items differ from “out of stock” inventory, which has no set replenishment dates.

How Do Backorders Happen?

In a perfect world, sellers would never need to put items on backorder and would, instead, have the exact amount of necessary stock. Of course, we don’t live in that world, and retail businesses frequently run out of products, causing customer loyalty issues. A 2020 study on North American retail reported that unavailable products encouraged consumers to shop elsewhere, creating a $71.4 billion U.S. sales loss.

These supply issues happen for several reasons:

1. Supply Chain Disruptions

Manufacturing delays, shipping problems, or supplier shortages can prevent timely restocking.

World events also strain supplies. For example, 88.1% of respondents to the National Association of Manufacturers (NAM)

Q1 2022 Manufacturers’ Outlook Survey named supply chain shortages their primary challenge. NAM CEO Jay Timmons expected international issues to make their problems worse.

“The humanitarian crisis and economic disruptions of Russia’s war on Ukraine, as well as the resulting sanctions that manufacturers fully support, will exacerbate these supply chain challenges and could impact energy costs even more as we move into the second quarter,” he predicted in a press release.

In August 2022, the Anadolu Agency reported that natural gas and coal prices had set world records since Russia invaded Ukraine in February 2022, and European prices had increased by almost 128%. These hikes wreaked havoc on global supply chains and energized efforts to find more reliable energy sources.

Extreme weather can wreak havoc on supply chains, as well. The 2021 Texas Freeze covered the state with snow and ice as temperatures dropped as low as six degrees Fahrenheit.

According to the Environment Texas Research and Policy Center, 69% of the state’s population lost power for an average of 42 hours. Of course, these blackouts caused significant disruptions for manufacturers since railroads and factories closed for days.

“The weather disruption tightened motor fuel supplies, created shortfalls of petrochemicals, and slowed Texas exports,”

Jesse Thompson reported

for the Federal Reserve Bank of Dallas. “The impacts to supply chains have contributed to rising producer price inflation, and the challenges of restocking those supply chains are expected to persist through much of 2021.”

2. Unexpected Demand

Sudden demand spikes can outpace a company's inventory, leading to stock shortages. We saw this situation occur frequently during the COVID-19 pandemic. The 2021 State of Manufacturing Report from Oden Technologies surveyed 800 manufacturers and discovered that many were seeing a 25% to 50% increase in product demand at the time. However, many companies couldn’t keep up, and over half could only increase their production capacity by 6% to 10%.

3. Limited Production Capacity

Some products, especially those requiring specialized manufacturing processes, may have limited production capabilities. Consequently, vendors must backorder items when demand exceeds this capacity.

For example, let’s say a small clothing company can only produce a certain number of skirts on its machines. If demand exceeds supply, the company will have to move buildings before it can purchase more machines and increase production. That’s not easily done, so the skirts must go on backorder.

4. Inventory Mismanagement

Poor forecasting and inventory control can leave stock levels unaligned with actual demand. In fact, inventory distortion has become a $1.9 trillion issue globally, according to Business Wire.

Fortunately, the software industry has made significant strides in recent years, and ERPs have become one of a manufacturer’s greatest tools for inventory management. For instance, NetSuite offers tools for tracking inventory in multiple locations, identifying reorder points, handling safety stock and cycle counts, forecasting, and demand planning.

This technology helps predict how much product to manufacture without sinking too many funds into surplus inventory. Schedule a free consultation with SuiteDynamics experts to learn more about NetSuite’s inventory management capabilities and discover how productive your company can become.

The Impact of Backorders

Many companies offer backorders because they increase sales and free up overhead and storage space that may otherwise be taken by excess stock. Yet, backorders can still negatively impact businesses and customers.

1. Customer Dissatisfaction

For customers, backorders can mean delayed gratification and uncertainty about whether they will receive their items at all. Or a backorder status may change a consumer's mind about a purchase. The Baymard Institute found that 23% of customers abandoned their carts during checkout if the shipping time was too slow. And if people don’t want to wait for a slow shipment, they definitely won’t appreciate a backorder.

2. Revenue Delays

Companies must deal with deferred revenue until the product is restocked and shipped, affecting cash flow.

3. Increased Administrative Costs

Managing backorders requires additional resources to handle customer inquiries and update inventory systems. Research from F. Curtis Barry & Company reports that backorders can cost $15 to $20 per fulfillment. Therefore, your company should only offer them for products with sufficient profit margins to cover the extra cost.

Managing Backorders Effectively

Businesses can adopt several strategies to minimize adverse backorder effects and manage them efficiently.

1. Accurate Demand Forecasting

The advanced analytics and historical data provided by systems like NetSuite can help predict demand more accurately and align inventory levels accordingly.

2. Supplier Relationships

Strong supplier relationships can ensure more reliable and flexible sourcing, helping to mitigate supply chain disruptions.

3. Inventory Buffer

A safety stock or buffer inventory can cushion against unexpected demand spikes and supply chain issues.

4. Transparent Communication

Reduce frustration and build trust by informing customers about their order statuses and expected delivery times.

5. Order Prioritization

Implement a system prioritizing backorders based on factors like order date or customer importance, ensuring fair and efficient fulfillment.

6. Diversifying Suppliers

Rely on multiple suppliers to reduce backorder risks due to supplier-specific issues.

What is a Backorder Rule?

A backorder rule is a set of predefined guidelines or criteria that a company uses to manage and fulfill orders for products that are temporarily out of stock. These rules help determine how backorders should be processed, prioritized, and communicated to customers.

A backorder rule’s primary goal is to ensure that customers receive their orders as soon as possible while maintaining efficient inventory management.

For example, let’s say a retail company has established a backorder rule stating that if a product is out of stock but expected to be available within 30 days, customers can place orders for the product. According to the guidelines, these orders will be fulfilled on a first-come, first-served basis once the product is back in stock. Customers will be informed of the expected restock date when they order.

Benefits of Using Backorder Rules in NetSuite

If your company must offer backorders, NetSuite ensures you can do it in the most efficient way possible. The software offers various benefits that ease the backorder burden.

1. Enhanced Customer Satisfaction

Transparent communication and efficient backorder management help maintain customer satisfaction even when items are out of stock.

2. Optimized Inventory Management

Accurate demand forecasting and automated replenishment reduce the frequency and impact of backorders.

3. Streamlined Operations

Automation and prioritization rules ensure that backorders are handled efficiently, reducing administrative overhead and manual intervention.

4. Informed Decision-Making

Access to real-time data and comprehensive reports allows businesses to make informed inventory and order management decisions.

Schedule a free consultation with SuiteDynamics to discuss NetSuite further or watch a system demonstration. We’ll show you how well your operations can run with quality software.

Setting Up Your Backorder Preferences in NetSuite

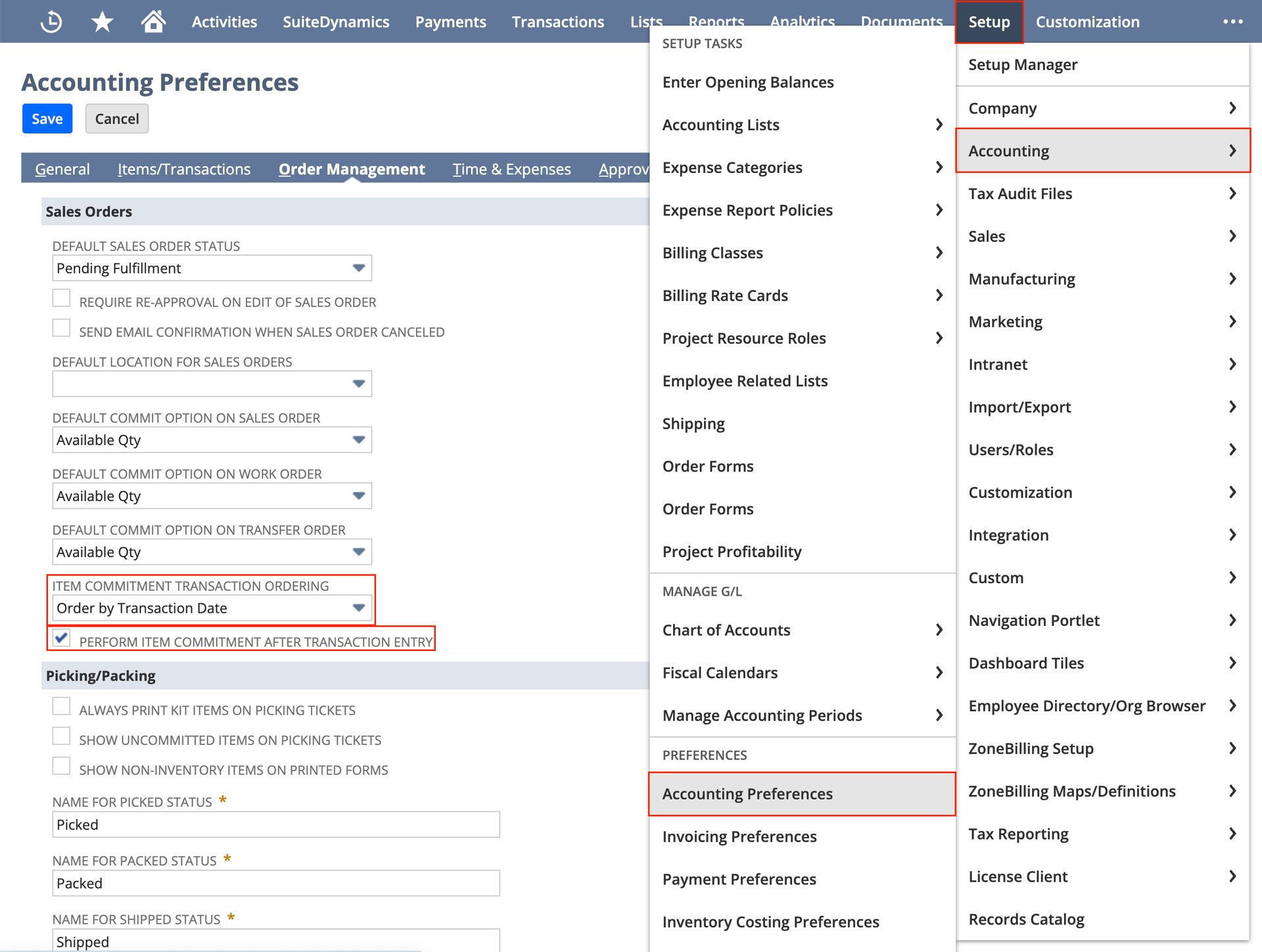

Navigate to Setup > Accounting > Accounting Preferences. Under the Order Preferences tab, there are two fields that impact the backordering process and determine when items are allocated.

- Item Commitment Transaction Ordering: The three options in this drop-down menu indicate which sales orders will have their backordered quantities filled first.

- Order by Expected Ship Date: fulfills backorders based on the latest expected ship date.

- Order by Order Priority: fulfills backorders based on a custom field on the transaction, such as work order, sales order, or transfer order.

- Order by Transaction Date: fulfills backorders based on the latest transaction date.

- Item Commitment After Transaction Entry: When this is checked, NetSuite will automatically allocate items based on the drop-down selected above. However, if you have not checked the box, you must manually create the backordered shipments.

How Backorder Rules Work in NetSuite

NetSuite provides robust backorder management features through its inventory and order management modules. Here’s how to implement and utilize backorder rules within NetSuite.

Creating and Managing Backorders

Order Entry: NetSuite lets you see real-time inventory levels when entering a sales order. If an item is out of stock, the system automatically creates a backorder for the out-of-stock quantity.

Backorder Notifications: You can configure NetSuite to send automatic notifications to customers informing them of the backorder status and expected delivery dates. This transparency helps manage customer expectations and maintains trust.

Prioritizing Backorders

Sales Order Priority: NetSuite enables businesses to prioritize backorders based on criteria such as order date, customer importance, or specific product lines. This ensures high-priority orders are fulfilled first once inventory is replenished.

Allocation Rules: Use allocation rules to determine how new inventory should be distributed among existing backorders. These rules can be customized to align with business priorities and customer commitments.

Inventory Replenishment

Automated Replenishment: NetSuite’s advanced inventory management capabilities can automate the replenishment process. When inventory levels fall below a certain threshold, NetSuite can generate purchase orders or transfer orders to restock the items.

Vendor Management: Manage relationships with suppliers to ensure timely restocking of backordered items. NetSuite’s vendor management tools help track purchase orders, lead times, and delivery schedules.

Order Fulfillment

Partial Shipments: NetSuite allows for partial shipments if a customer order contains multiple items, some of which are available while others are backordered. This ensures customers receive the available items promptly while waiting for the rest.

Backorder Reporting: Use NetSuite’s reporting and analytics tools to track backorder trends, identify recurring issues, and optimize inventory levels. Monitoring backorder reports can help improve demand forecasting and inventory management practices.

You can ask for further information on these features during your free consultation with SuiteDynamics experts. We’ll discuss how NetSuite’s tools can solve your company’s issues, improve operations, and skyrocket profitability.

Create a Backorder Process That Makes Customers Happy

Backorders are a necessary pain. If you’re in the retail business, you’ll probably have to deal with them. Still, effective strategies, proactive management, and intelligent software choice can minimize their impact on your company.

A NetSuite ERP system streamlines the backorder process, facilitating better customer communication, automating replenishment, and identifying inventory trends. It also helps increase forecast accuracy so you can better avoid supply issues in the first place.

Schedule a free consultation with SuiteDynamics experts to discuss how a NetSuite ERP system can help solve inventory management problems, streamline production, and increase customer satisfaction.

We pull information from NetSuite material, SuiteDynamics experts, and other reliable sources to compose our blog posts and educational pieces. We ensure they are as accurate as possible at the time of writing. However, software evolves quickly, and although we work to maintain these posts, some details may fall out of date. Contact SuiteDynamics experts for the latest information on NetSuite ERP systems.

Part of this text was generated using GPT-3, OpenAI’s large-scale language-generation model. After generating the draft language, our team edited, revised, and fact-checked it to ensure readability and accuracy. SuiteDynamics is ultimately responsible for the content of this blog post.